Active in the wholesale production of frame moulding since 1975, Imex has always been sensitive to technological evolution and inclined to continuous improvement, not only in terms of production output, but also in view of increasing the efficiency of internal workflows.

Recently, the company needed to implement a tool that could prove useful in controlling the production of frame mouldings and all other products derived from woodworking, and in cost control. This is how “i.mes” was born.

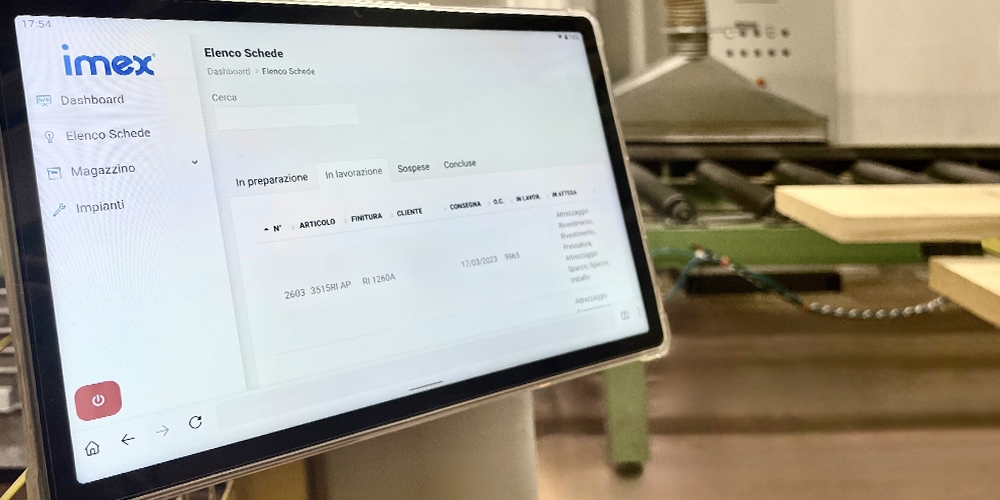

i.mes (acronym of Imex MES), created by Valeo Studio, is a computer system developed ad hoc with the aim of facilitating the management and control of production activities.

This new tool allows us to optimize and coordinate the company’s workflow, including the launch of orders into production, monitoring the progresses, managing the stocks of raw material, the maintenance of machinery/production plants for the production of our frame mouldings, and all the related documentation.

How does i.mes work?

This complex but intuitive software collects production data through manual inputs and makes them available in real time to the offices, allowing everyone to have a complete view of the progress and physical state of the stocks and materials used. The collected data is then archived and will be available, in the future, for reporting and analysis purposes.

The real strength of i.mes? The fact that it’s a solution created ad hoc for the needs of our company that adapts to our production logics without distorting them, that is modeled on our systems and that allows us to gradually implement new functions.

The production of frame mouldings and other wooden products is an activity that we are now able to manage in the best possible way, with the maximum control of every phase.